High-Performance Polymers: Advanced Materials for Industry

High-Performance Polymers: Advanced Materials for Industry

Blog Article

From Manufacturing to Medication: How Polymers Revolutionize Numerous Markets With Their Advantages

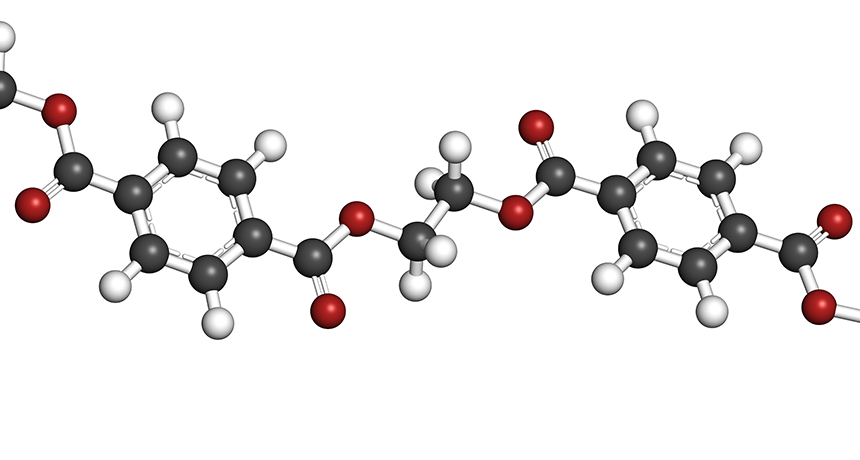

Polymers, with their varied chemical structures and adjustable homes, have become pivotal elements across a range of industries. From boosting manufacturing processes to allowing cutting-edge innovations in medicine, the effect of polymers resounds everywhere. Their flexibility and versatility have not just reinvented product development in industries like vehicle and electronics yet have additionally introduced a new era of clinical improvements. As we check out the detailed methods which polymers have improved different markets, it becomes obvious that their benefits extend past traditional boundaries, using a peek into a future where possibilities seem infinite.

Adaptability in Production

With their varied residential properties and versatility, polymers have actually dramatically improved the manufacturing refines throughout numerous industries. The versatility of polymers in manufacturing is credited to their capacity to be formed right into complex forms, their light-weight nature, toughness, and resistance to rust. These residential or commercial properties make polymers a perfect choice for a large range of applications, from auto and aerospace industries to healthcare and electronics.

In the automobile sector, polymers are thoroughly made use of in producing elements such as bumpers, control panels, and interior trims due to their lightweight nature, which helps enhance gas effectiveness. Additionally, their durability and resistance to corrosion make them suitable for outdoor applications in building and construction and facilities tasks. In the healthcare industry, polymers play an essential role in producing clinical gadgets, devices, and product packaging materials due to their biocompatibility and sterilization capacities.

Enhanced Product Efficiency

Substantial improvements in product efficiency have actually been accomplished via the assimilation of polymers in numerous industries. Polymers contribute considerably to enhancing item performance because of their special residential properties and convenience. In the vehicle sector, the usage of polymers in making components such as bumpers and interior parts has actually led to lighter vehicles, improved fuel efficiency, and boosted longevity. The aerospace industry advantages from polymers in the production of light-weight yet strong products for airplane, causing improved efficiency and lowered upkeep costs - Polymers.

Furthermore, in the electronic devices industry, polymers play an important duty in improving the performance of devices through their insulating buildings, effect resistance, and adaptability. This allows for the growth of smaller sized, extra efficient digital products that are likewise a lot more long lasting. In the medical field, polymers are utilized to develop sophisticated implants and drug shipment systems that supply enhanced biocompatibility and targeted therapy, eventually improving client results.

Developments in Medical Gadgets

The application of polymers in the clinical area has actually resulted in groundbreaking innovations in the development of advanced medical gadgets. Polymers have revolutionized the design and performance of clinical tools by providing unique residential or commercial properties such as biocompatibility, flexibility, and durability. One this page noteworthy advancement is making use of polymer-based products in the manufacturing of implantable devices like man-made joints, stents, and catheters. These tools are currently more suitable with the human body, decreasing the threat of denial or negative responses.

Polymer compounds have actually additionally enabled the creation of lighter and much more comfy prosthetics, enhancing the quality of life for amputees. Polymers with antimicrobial residential or commercial properties are being incorporated into medical gadgets to prevent infections and improve patient end results. The growth of advanced medication shipment systems utilizing polymer-based materials has actually reinvented the treatment of different diseases by making sure targeted and controlled release of drugs.

Drug Distribution Developments

In the world of pharmaceutical improvements, unique drug delivery systems are improving the landscape of medical treatment. These advancements intend to improve the efficacy and precision of drug administration while decreasing side results and enhancing person compliance. Among the crucial innovations in drug shipment is the use of polymer-based providers. Polymers supply a versatile platform for creating delivery systems that can control drug release rates, target particular cells or cells, and safeguard the medicine from destruction in the body.

Nanotechnology has additionally played an essential duty in medicine distribution advancements by making it possible for the growth of nano-sized medicine carriers. These nanocarriers can boost drug solubility, lengthen flow time in the body, and improve mobile uptake, inevitably resulting in boosted therapeutic results. Advancements in tailored medicine have led to the customization of medicine distribution systems based on specific patient qualities, such as hereditary make-up or disease profile.

Lasting Solutions

Having laid the foundation for innovations in medication delivery systems, the emphasis now changes towards exploring lasting remedies within the realm of polymer-based service providers. Sustainability has actually come to be an essential facet of modern-day markets, including health care, driving find more info the requirement for environmentally find out here friendly options. Polymers provide an appealing avenue for addressing sustainability challenges due to their flexibility, biodegradability, and recyclability.

One secret aspect where polymers contribute to sustainability is in reducing the ecological impact of medical waste. Naturally degradable polymers can be made to break down naturally gradually, lessening the accumulation of non-degradable materials in garbage dumps. Furthermore, the recyclability of certain polymers enables the growth of closed-loop systems that advertise the reuse of resources, further reducing waste manufacturing.

Furthermore, the usage of sustainable sources for polymer manufacturing, such as plant-based sources like corn or sugarcane, offers a chance to lower reliance on nonrenewable fuel sources and reduced carbon exhausts. By harnessing the possibility of polymers as sustainable remedies, industries can move towards more ecologically pleasant techniques without endangering performance or performance.

Conclusion

In conclusion, polymers have actually considerably changed different industries, consisting of production and medicine, due to their flexibility, enhanced product efficiency, and cutting-edge applications in medical tools and drug delivery systems - Polymers. These innovations have brought about the growth of sustainable services that benefit both sectors and the environment. Polymers remain to play a vital role in driving development and progress across different industries, showcasing their relevance in modern-day culture

Report this page